Rebar Software

Rebar software helps structural engineers and rebar detailers produce an accurate and comprehensive set of reinforcement documentation. These reinforcement drawings are used to fabricate the rebar and ensure it is installed correctly on site.

Table of contents:

- Why Do You Use Rebar For Concrete?

- What Is Meant By Rebar Detailing?

- What Is Rebar Software?

- Rebar CAD Software Free Download

- Learn More About Rebar Software

- Further Learning

Why Do You Use Rebar For Concrete?

Concrete has high compressive strength but very weak tensile strength. Steel reinforcement (often called rebar) is included within the concrete to provide the tensile strength that concrete typically lacks.

For precast and poured in-situ concrete, the required rebar is formed into a reinforcement cage before the concrete is poured and cures. The cage is created by fixing bars of reinforcement together with ties or clamps. In some cases, the rebar will be welded together. Once the rebar is in place, the concrete is poured around the cage and allowed to cure. The rebar also has a textured or ribbed surface so that a mechanical bond is created between the rebar and the concrete.

What Is Meant By Rebar Detailing?

Rebar detailing is creating the concrete reinforcement placing drawings (sometimes called the shop drawings) used to fabricate and install the required rebar. Rebar detailing may also be called rebar scheduling, RC detailing, RC drafting, or bar bending schedule preparation. The design (or engineering) drawings will show some rebar information. However, the steel fabricators and on-site workers who will install the reinforcement (for poured in-situ concrete) cannot work from these drawings. Instead, this information is included in the rebar placing drawings.

Each reinforcement bar needs to be cut to a specific size and may need to be bent into a particular shape to fit within the concrete component. The placing drawings contain more detailed information than the design drawings, such as the bar size and type, their placement, the bending shapes used, and the placing or fixing sequence. One of the most important aspects of placing drawings is the bar bending schedule, which lists the number and size of the different bent shapes required in the project.

What Is Rebar Software?

Rebar detailing software helps structural engineers create an accurate and comprehensive set of reinforcement documentation, which includes the placing drawings and the bar bending schedule. With 2D CAD software, creating the placing drawings is an onerous task, requiring several operations and drawings. 3D rebar CAD software such as Allplan Engineering significantly simplifies this process. Any component can be quickly and easily reinforced with the built-in tools and then adjusted to the correct dimensions and properties. The detailing is completed as the reinforcement is modeled, with annotations and tags added and pre-filled with the information already present in the model, such as bar size. This makes the detailing process much quicker as well as more accurate. Finally, by using the reporting features in rebar detailing software like Allplan Engineering, the bar bending schedule can be created in just a few clicks. Simply use the included templates that are based on commonly used codes or create a custom report that will display the desired bar bending schedule information.

Learn More About Rebar Software

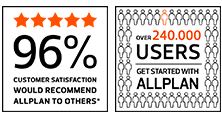

See how these companies used ALLPLAN’s rebar CAD software to greatly increase the efficiency of the rebar detailing process. Request a personal demo today to find out just how easy it is to upgrade the detailing process and overall design performance.

Webinar - Rebar Management: From Fabrication to Construction

Webinar - Rebar Management: From Fabrication to Construction

Tips and Tricks for Rebar Modeling

In this webinar, we will show you how to manage your rebar using the project model data as the single source of truth. From the model, we will show you how to synchronize your bar information bi-directionally with your rebar fabrication manager, whether as a Soule or an Excel spreadsheet!

We will demonstrate how seamlessly you can manage releases, shapes, changes, and bar status and track your bars right through to placement.

Dimensional BIM Software

Dimensional BIM Software

Model your next project in dimensional views that fit your project needs, not your technological capability. Give your company the best in advanced modeling technology with Allplan's wide range of BIM visual software. Explore the full range of capabilities below.

Bring BIM to Buried Structures

Bring BIM to Buried Structures

Buried structures require special attention and design to meet your particular project requirements. Being the foundation of any vertical construction endeavor, it's imperative to get it right the first time to avoid future conflict in design. Find out how Allplan prepares engineers and project managers for the complexity of buried structures with collaborative features and intuitive processes.